High Temp. MgO GSM1A-1

● Features

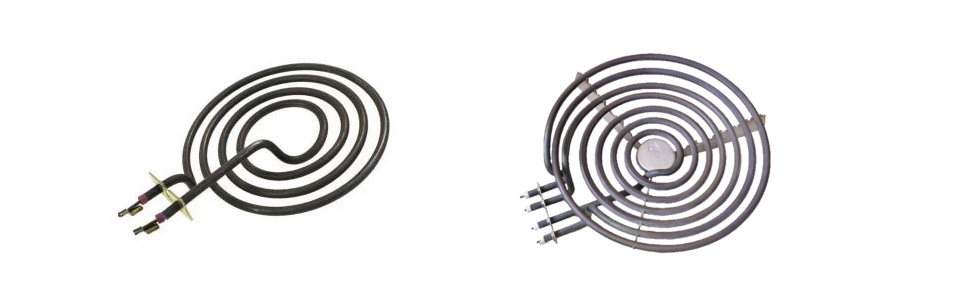

GSM1A-1 is high temperature MgO powder, mainly used in air heating elements, such as grill and oven heating elements. It can stand 1050℃ heating treatment. Immediate sealing is required after annealing.

● Chemical Analysis

| Composition | MgO | CaO | Fe2O3 | Al2O3 | SiO2 |

| Value (%) | ≥96.5 | ≤1.3 | ≤0.55 | ≤0.9 | ≤3.5 |

*The properties are the typical values and not the guaranteed values.

● Physical Properties

| Flow Rate | Tap Density | Particle Size Distribution |

| 150±20s/100g | 2.28~2.41g/cm3 | 50~325 |

● Particle Size Distribution

| Mesh | +50 | +60 | +80 | +100 | +150 | +200 | +325 | -325 |

| Particle Size (μm) | +355 | +280 | +180 | +154 | +100 | +71 | +46 | -46 |

| Value (%) | 0~10 | 16~28 | 26~38 | 2~10 | 14~26 | 10~20 | 1~9 | 0~3 |

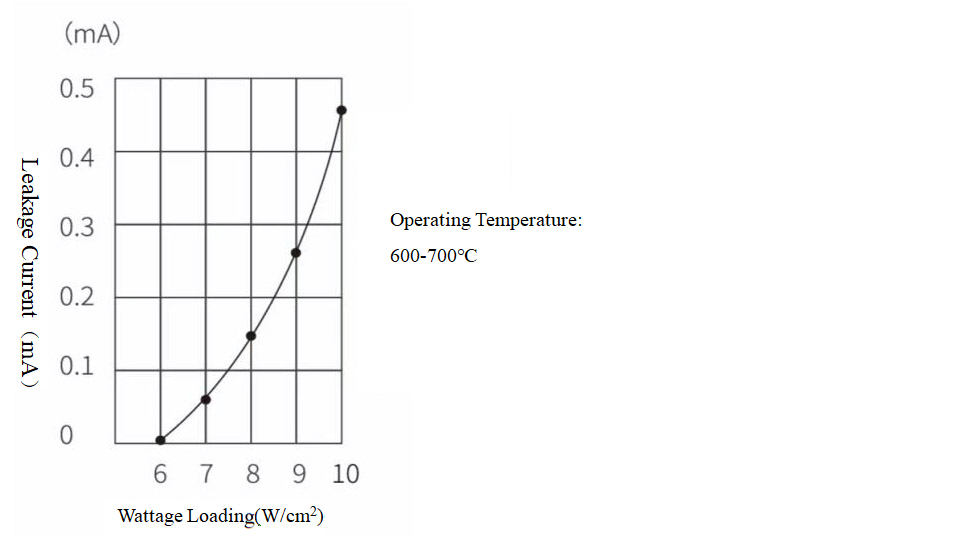

● Electrical Properties

GSM1A-1(MgO≥96.5%)

● Test Conditions

Material: SUS304

Rolling: ɸ8.0mm→ɸ6.6mm

Core rod:Ni80Cr20,Φ0.3mm

Effective Heating Length: 43.0-47.0cm

Cold Insulation Resistance: 28Ω-33Ω

Power on Time:15min

*The properties are the typical values and not the guaranteed values.

● Packaging

25Kg in a woven bag. Special Package is available on requirements.

● Remarks

1. GSM1A-1 is treated without silicone or treated with pretty light silicon oil.

2. GSM1A-1 is mainly used in air heating with wattage loading less than 9W/cm2.

3. Electrical grade MgO powder is non-toxic, but with some dust. It is recommended to wear anti-dust respirators and gloves during operation.

4. The elements can stand 1050℃ annealing for 15-30 minutes and requires immediate sealing.

5. Electrical grade MgO powder should be stored in dry places, and best used within 6 months after delivery.