Special High Temperature MgO for High Power Cartridge Heater G1-1(Marine Magnesium)

● Features

G1-1 is mainly used for high-power cartridge heaters. The raw material is fused magnesium using the magnesite derived from seawater with chemical methods and fired at 2700°C. It has low SiO2 and extremely high heat resistance and slag resistance.

This kind of MgO powder has MgO ⩾99%, extremely low Fe2O3, higher whiteness, and good electrical properties. It can be applied in cartridge heaters with surface loading ⩽10W/cm2, and the leakage current is less than 0.2mA.

● Chemical Analysis

| Composition | MgO | CaO | Fe2O3 | Al2O3 | SiO2 |

| Value (%) | ≥99.0 | ≤0.5 | ≤0.2 | ≤0.1 | ≤0.5 |

● Physical Properties

| Flow Rate | Tap Density | Particle Size Distribution |

| 155±15s/100g | 2.27~2.38g/cm3 | 60~325 |

● Particle Size Distribution

| Mesh | +60 | +80 | +150 | +200 | +250 | +325 | -325 |

| Particle Size (μm) | +280 | +180 | +100 | +71 | +55 | +46 | -46 |

| Value (%) | 8~20 | 28~38 | 26~36 | 10~20 | 2~8 | 1~6 | 0~5 |

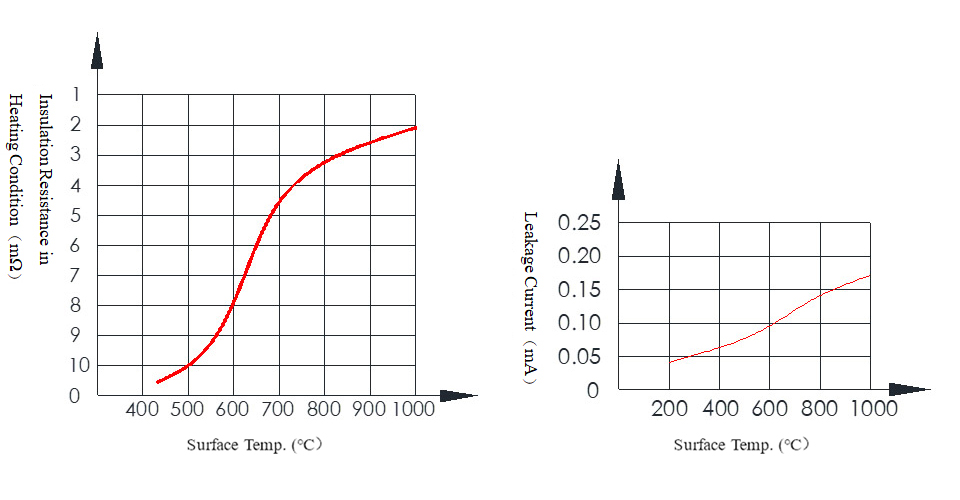

● Electrical Properties

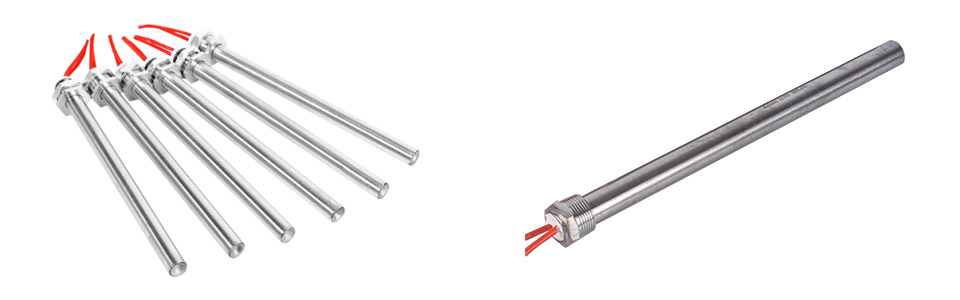

● Test Condition

Material: SUS304

Rolling: ɸ8.0mm→ɸ6.6mm

Length: 450mm

Surface Loading: 7W/cm2

Power on Time:20min

*The properties are the typical values and not the guaranteed values.

● Packaging

5Kg in a woven bag. Special Package is available on requirements.

● Remarks

1. G1-1 is treated without silicone or treated with pretty light silicon oil.

2. Electrical grade MgO powder is non-toxic, but with some dust. It is recommended to wear anti-dust respirators and gloves during operation.

3. The elements can stand 1050℃ annealing for 15-30 minutes and requires immediate sealing.

4. Electrical grade MgO powder should be stored in dry places, and best used within 6 months after delivery.